Case Studies - Download section

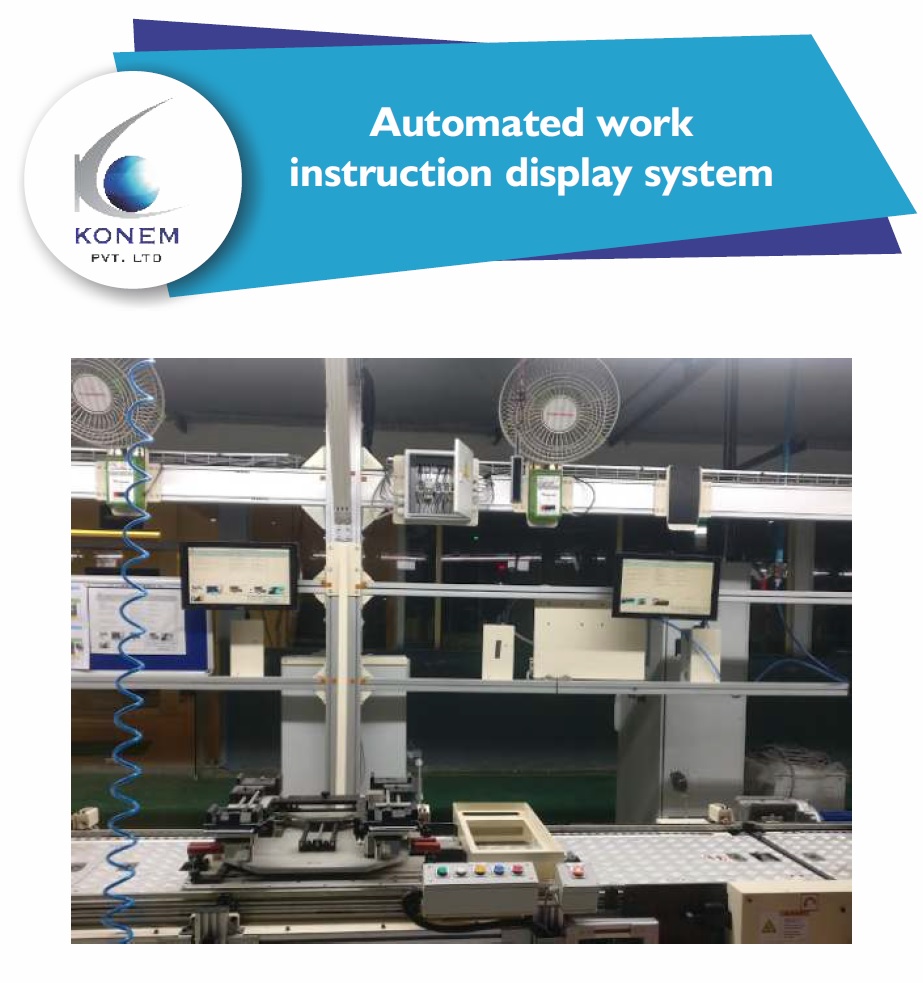

TIRED OF YOUR OLD STATIC PAPER BASED WORK INSTRUCTION SHEET. KONEM PROVIDES YOU WITH DIGITAL WORK INSTRUCTION DISPLAY THAT CAN BE AUTOMATED TO SUIT YOUR NEEDS

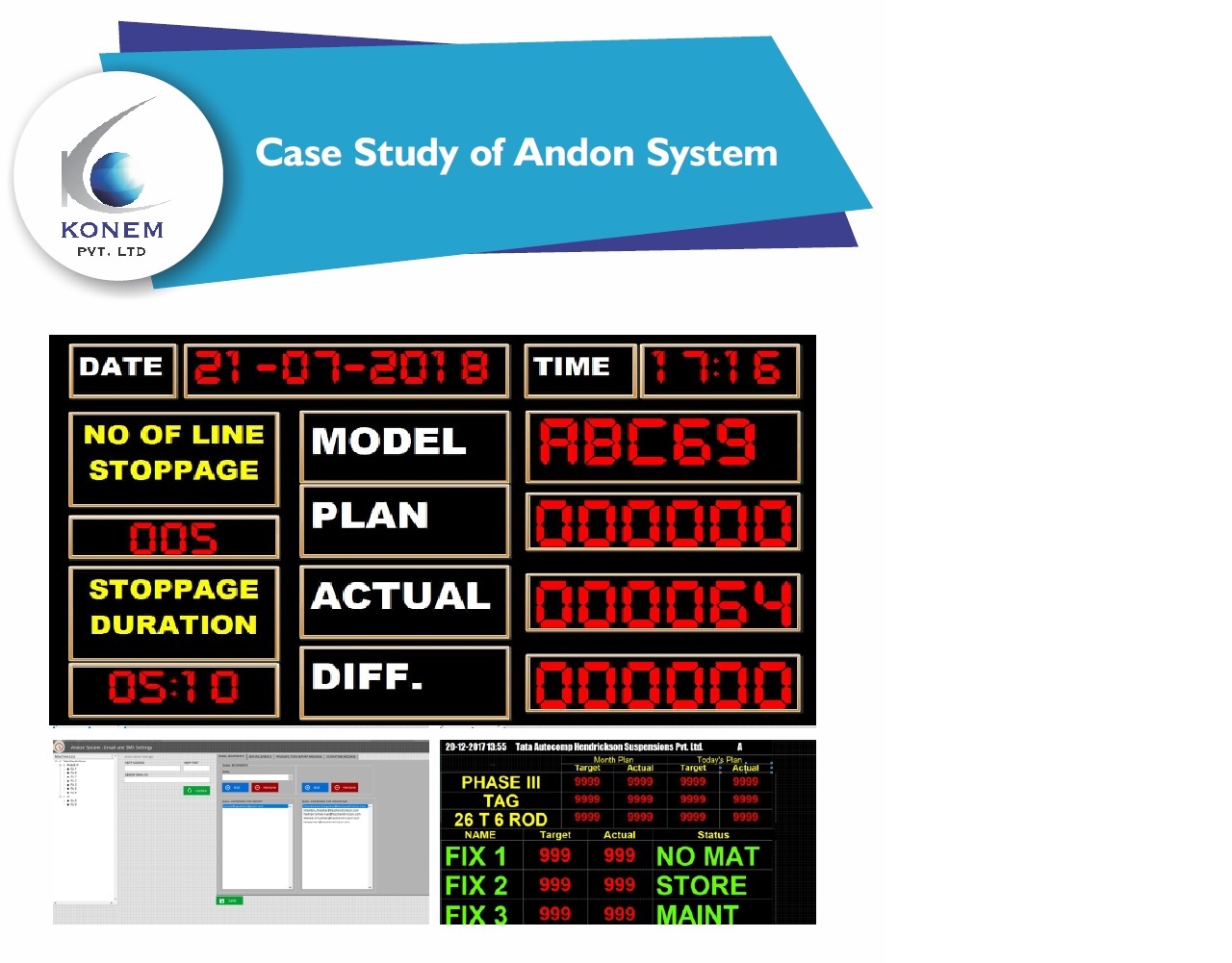

SOPHISTICATED SOFTWARE AND HARDWARE SOLUTION WHICH PROVIDES YOU COMPLETE PRODUCTIVITY DETAILS OF YOUR MACHINE WITH OEE CALCULATIONS.

THIS MACHINE IS AN EOL/FTM MACHINE TO TEST TILT / ROLLOVER ANGLE SENSOR. COMPLETE AUTOMATED TEST BENCH. MULTIPLE DUT'S ARE TESTED TO ENSURE HIGH PRODUCTIVITY

IN INDEXING MACHINE WAS AUTOMATED WHICH WAS USED FOR HEAT SINK FILLING IN THE TEMPERATURE SENSOR. VISION CAMERA AND SERVO SLIDES WERE USED IN AUTOMATION

THIS AUTOMATED TEST BENCH CHECKS FOR ELECTRICAL AND ELECTRONIC COMPONENTS IN THE 2 TYPES OF BUMPER FRONT AND REAR. PARKING SENSOR, KICK SENSOR, FOG LAMPS, ETC

APS EOL ATE IS STATE OF AN ART PROGRAMMING AND TESTING MACHINE, WHICH PROGRAMS A LINEAR RATIOMETRIC HALL IC AND CHECKS FOR THE LINEARITY & HYSTERISIS IN EOL.

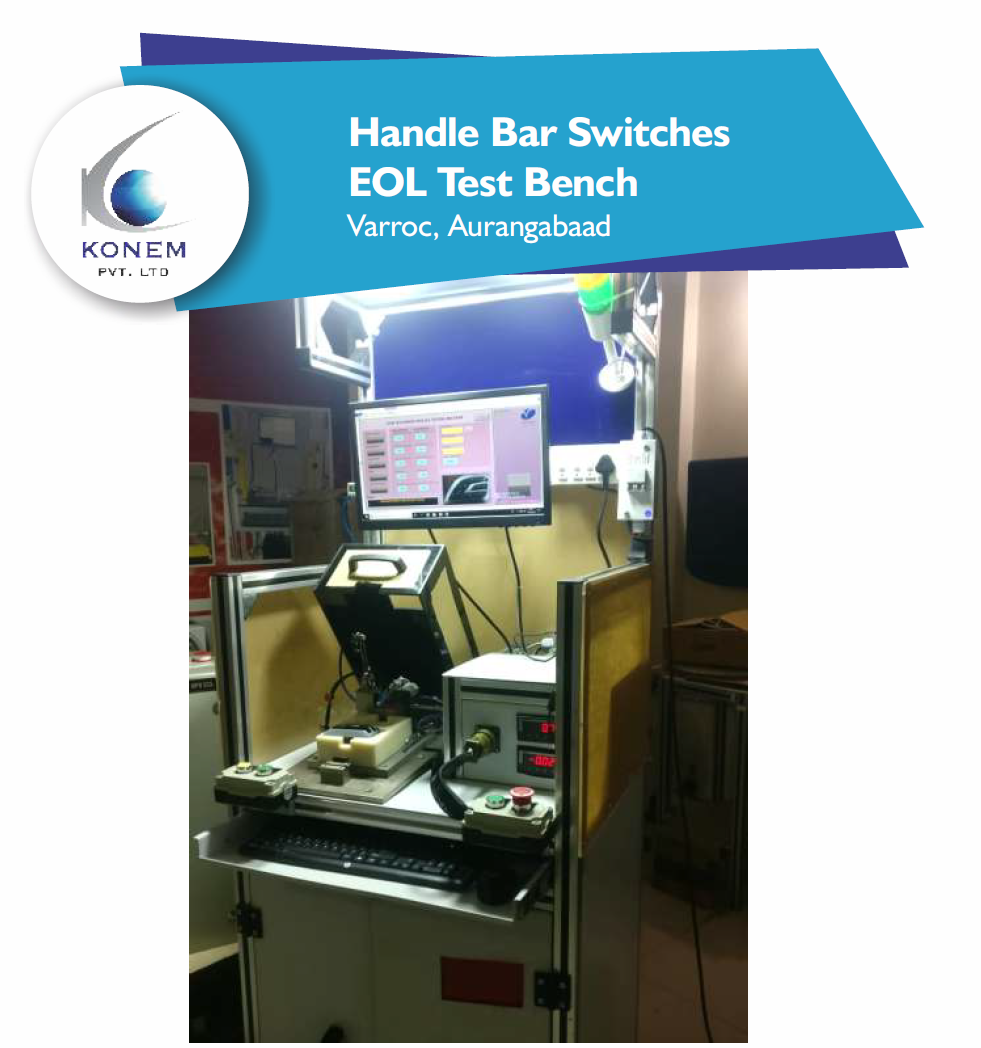

THIS TEST BENCH CHECKS FOR THE LH HANDLE BAR SWITCH ON ACTUAL VEHICLE LOAD. TESTING OF THE DUT IS THROUGH PLC & HMI SOFTWARE.

TPS EOL ATE IS STATE OF AN ART PROGRAMMING AND TESTING MACHINE, WHICH PROGRAMS A LINEAR RATIOMETRIC HALL IC AND CHECKS FOR THE LINEARITY & HYSTERISIS IN EOL.

THIS SORTING MACHINE IS USED TO SORT PLASTIC COMPONENTS CALLED PISTON, WHICH MAY HAVE ABRASIVE PARTICLES STUCK IN IT DURING ITS POLISING OR BUR REMOVAL STAGE.

THIS TEST BENCH CHECKS FOR THE NEWEST TYPE OF HANDLE BAR SWITCH WHICH ARE NON CONTACT TYPE OR HALL IC BASED. TESTING OF THE DUT IS THROUGH LABVIEW SOFTWARE.

RESISTANCE AND SHAFT LENGTH IS BEING VERIFIED IN THIS SMALL FOOTPRINT BENCH TOP TEST BENCH. MIXUP OF SIMILAR LOOKING VARIANTS ARE AVOIDED BY THIS MACHINE

OPEN SPARK TEST MACHINE PROVIDES A SPARKING ENVIRONMENT WHERE EMI NOISE IS INDUCED TO CHECK FLICKERING IF ANY IN THE AUTOMOTIVE CLUSTER.

Handle bar switch endurance test rig provides user an endurance facility to check multiple functions of a switch at different conditions for extended period.

AUTOMATED TEST BENCH TO TEST VARIOUS CDI'S ON AN AUTOMATED TEST BENCH, MAGNETO SETUP TO PROVIDE VEHICLE LEVEL SIGNALS TO CDI AND NI AND LABVIEW BASED PANEL

THIS MACHINE USES PRECISE SERVO CONTROL AND HIGHLY PRECISE LOAD CELL AND LVDT TO ACHIEVE THE POINTER PRESSING IN THE MOTOR SHAFT OF CLUSTER IN REAL TIME CONTROL